Lace Production Line – How The Beautiful Lace Come Out?

Most of our customers are buying lace fabric and lace trim regularly from us for long time, they know something about the production after visiting our factory but don’t know clearly, so I think it is necessary and meaningful to write a post to introduce the detail production line of lace.

The entire lace production can be divided into eight parts as below.

Craft – Yarn Preparation – Weaving – Lab Dip – Dyeing – Heat Setting – Cutting – Packing

Is it complicated? Don’t worry, let’s see the details one by one, then you will be clearly and professional.

1, Lace Craft

Every lace deign has a corresponding craft, it decide the surface of lace. Our experienced designers draw the craft in computer by special software. There are two situations. First one, create a new design, this means the designer draw the lace craft by their own idea. Another one, draw a craft according to a real sample. This situation happens when customer gives us a real sample and let us produce it for him. Before we produce it, we will let our designer analyze the real sample and draw the craft of it.

Normally, customers don’t care about the craft even never seen it, they only care about the real sample, but the craft is very important for our lace production, it will tell us which machine should we use to produce the design, also the cost. The most important is that it also works like a computer program, we input it to the machine, then the machine knows how to produce.

2, Yarn Preparation

There are many needles in one machine, and different needles use different yarn like nylon, spandex or rayon, so before the machine start production, we should prepare all the needles and yarns and make sure all setting are in right position. This is a huge work, when we change the design in the same machine, it always take us about 5 days to change yarns to make everything ready.

3, Lace Weaving

Now, yarns are well prepared, the machine also have the craft program inside, we can start the weaving! The machine is automatic, so the workers can rest now? No! Machines are like kid, lovely but naughty. We should let nanny – workers to take care of them in 24 hours. Because problems will appear in any time, like some yarns are used up, some yarns broken or have holes in the fabric etc., When problem happen, our experienced workers will stop the machine and solve it.

The lace fabrics from weaving machine is called “greige”, its not flat, can’t be used to garment or lingerie directly.

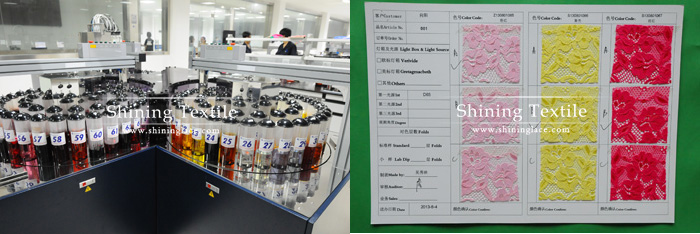

4, Make Lab Dip

This is the first step of dyeing. Dyeing laboratory make lab dip as per color swatch or Pantone color code submitted. We offer A, B, C or more choice each color for your approval. We adopt your comments on lad dip and make new lab dip if necessary until you find the right one. Bulk dyeing will be strictly followed after lab dip confirmation.

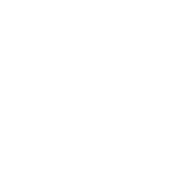

5, Dyeing Colors

Our dyeing house facilitated with more than 80 dyeing pots with different dyeing capacity, ranging from 50 kgs dyeing pots as MCQ for mixed color dyeing and 2000kgs dyeing pot to make mass dyeing in one time. The dyeing capacity is 15 tons daily. The greige stay in the dyeing pots for 5-20 hours according to the color shade and requirements, also related to the composition. After dyeing, we will send you the bulk sample for approval.

6, Heat Setting

The goods go for heat setting after bulk dyeing, some people also call it presetting. Why do this? We know that the greige is not flat, so we need to make it expand and flat. The presetting machine is about 20-30 meters long, fabrics will be in high temperature and high pressure when pass through it. Our strict experienced QC team inspect the quality during preset, they check the color , measure the width and pattern repeat, make sure that the elasticity consisting with the order submitted.

7, Cutting

The goods will be released from dyeing for next procedure of cutting only after we confirm everything meet standard. Actually lace fabric don’t need cutting, only lace trim need. Our cutting people is well trained, and skilled with cutting machine. They not only pursuit the high speed but also the best quality of cut lace to achieve high efficiency working conception. The cutting machines are well adjusted to the best position for lace of different cutting dimension. We ensure that every inch of our lace are cut with clear edge.

8, Packing

The cut lace go for rolling and are wrapped with transparent poly film and then packed in standard exporting carton. Fabric packing is by roll with transparent poly bag and then woven bag outside. The goods are well packed in order to protect them from broken or pollution during transportation.

Ok, our lace production are finished, you can take the beautiful lace now! It seems not that difficult, but every step need skilled and professional to control. Fortunately, we are good at this, and more fortunately, you have come to the right place by finding us – Shining Textile, your reliable lace manufacture and exporter in China.

My friend, are you clearly about the lace production after reading this? Please write me email if you still have any question.

Tommy: tommy@shininglace.com